Features

- Patented full steel Top surface.

- High induction of magnetic flux.

- High & uniform clamping power throughout the bed.

- Variable magnetic power possible.

- Perfect safety in case of power failure.

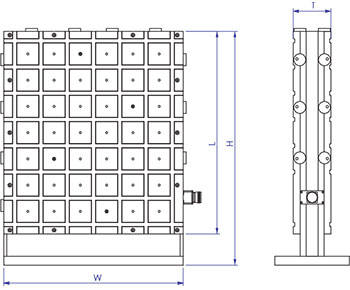

- 2 or 4 or multiple magnetic face.

- Unobstructed movement of tools during machining as all five faces of the job can be machined in the same setting.

- Drastically reduces the setup time and machining of the work pieces.

- Total magnetic surface used for clamping giving better machining accuracy as reducing chattering.

- 100% Leak Proof.

- Clamping force for EPCUBE 50 ≥ 350 kg/ pole.

- Clamping force for EPCUBE 75 ≥ 790 kg/ pole.

|

Applications

- Most suitable for milling operations on horizantal machining center.

- A minimum of 4/8 alternate poles contact is necessary for optimum clamping.

- Minimum thickness of job : 10-15 mm.

- Easily integrated with Pallet changing and FMS Systems.

- AUTOMATIC SHIMMING: Mobile pole extensions allow clamping and uniformly support work pieces even with uneven surfaces, achieving high accuracies of planarity.

- The Magnet can be designed for 220/380/400/480 VAC, 50/60 Hz.

- Custom designed solutions also available.

|

|